PGIOT RFID Power Resource Management Solution

Discover and eliminate hidden dangers in time to ensure the safety, stability and continuous operation of power system

In power system, substation equipment, transmission network, distribution network and optical fiber network are widely distributed. Exposed to the nature for a long time, the equipment not only bears normal mechanical load and load, but also suffers from pollution, lightning strike, strong wind, flood, landslide, enemy occupied, earthquake and bird damage, and even human external damage. In such a harsh environment, the components of power equipment on the line are prone to aging, fatigue, oxidation, corrosion and even damage. It is necessary to find and eliminate hidden dangers in time to ensure the safety, stability and continuous operation of the power system.

Limitations of traditional inspection methods

★Limitations of traditional inspection methods

★The power company shall arrange special personnel to be responsible for the inspection of power equipment;

★Including outdoor equipment and warehouse spare equipment.

★Inspection route control,The phenomenon of missing data is easy to occur;

★For special equipment such as high voltage or high altitude There are limitations in inspection;

★The back office managers lack of supervision over the inspectors,and it is easy to fill in the data indiscriminately when they are not on site;

★Inspection information cannot be returned in time;Paper and pen input method, data is not standardized, easy to make mistakes, low efficiency;

★There is a lack of sharing channels and query statistical methods for the data returned from the inspection.

PGIOT RFID power management solution

PGIOT RFID power management solution is based on the current situation of the power industry and the successful project accumulation in the power industry for many years, and combines modern computer communication technology, information technology, database technology and RFID technology,The management idea of patrol inspection is organically integrated into the system scheme,Make the inspection work truly safe, real-time, standardized, transparent and efficient.The scheme can be applied to all kinds of inspection methods of power enterprises,Including: power transmission / distribution line inspection and power station inspection.

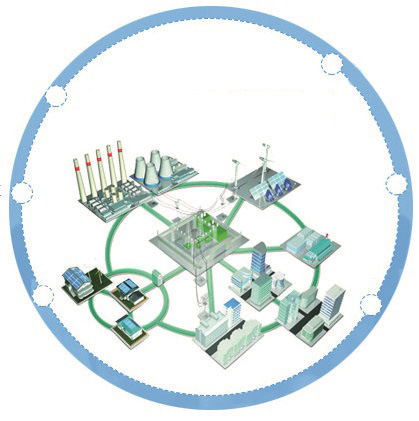

Solution system

architecture

Standardize the entry of equipment running status and defect information, which is convenient for statistics

PGIT RFID power management solution,RFID tags are used,Aging due to wind, sun, rain and dust is less affected

GPS technology and GIS system can be used to locate the patrol personnel in real time

Using RFID technology to exchange data over radio waves,

It can realize long-distance identification

Data collection and real-time return can be achieved by using mobile handheld terminal with RFID technology and a variety of communication technologies,The work efficiency of inspection personnel is improved

The inspection personnel complete the inspection work according to the inspection task, which makes the inspection work more standardized and orderly, and prevents management loopholes

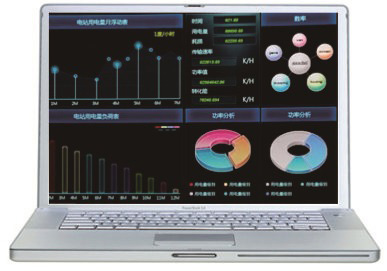

Main functions of the scheme

1.Basic setting management: including the formulation of inspection personnel, inspection area, inspection route and inspection items.

2.Equipment account management: complete the maintenance and query of equipment account

3.Patrol plan management: the patrol plan can be customized according to different inspection cycle (hour, day, week, month, etc.) or any time. After the plan is made, it will automatically trigger the execution and production inspection task.

4.Patrol task management: Patrol plan automatically generates patrol task, which can be downloaded to handheld terminal,

It can also query the historical data of the task

5.Patrol task execution: complete the patrol task through the handheld terminal, collect equipment data according to the inspection route,

and input the set operation status, operation parameters and defects.Among them, the defect situation of equipment will produce defect records

6.Defect management: maintain defect records generated during equipment inspection And deal with it.

7.The real-time positioning of inspectors can be realized through GPS signal and GIS system in the process of patrol monitoring and management.Historical and real-time inspection routes can also be carried out..

8.The interface function system can send the defect data to EAM system in the enterprise to generate defect repair work order.

Home About Us Product RFID Case Studies New Solution Contact

Contact Us

phone:0086-0752-2688768

Cellphone:0086-0752-2688768

E-mail:yedyyip@thinkgo.cc

Zip code:516000

Address:Huinan Science and Technology Innovation Center, Nangaoxin Science and Technology Industrial Park, Huizhou City, Guangdong Province, China

© Copyright pinguan.co. ICP No.: 粤ICP备19133779号-1 Powered by www.gdwl.net.cn

All rights reserved Thinkgo IOT ICP:19133779

*Some materials are from the Internet, if there is infringement please inform us, we will delete * within 24 hours

yedyyip@thinkgo.cc

Tel

0086-0752-2688768

Address

Building 2, Huinan Science and Technology Innovation Center, Huizhou City, Guangdong Province, China

All rights reserved Thinkgo IOT ICP:19133779

* Materials are from the Internet, if there is infringement please inform us, we will delete within 24 hours