RFID Warehouse Logistics Solution

PGIOT Make warehousing logistics more convenient

Traditional warehouse management adopts manual method, which is cumbersome, inefficient, human factors, low accuracy, easy to falsify data, waste of human resources, high management and maintenance costs, and it is difficult to ensure the correctness and timeliness of receiving, sorting, acceptance and delivery. Using RFID technology can significantly improve the production efficiency and reduce the cost

PGIOT RFID intelligent warehouse logistics solution

PGIOT RFID intelligent warehouse solution uses advanced information equipment instead of manual operation, and uses real-time wireless communication technology to replace the circulation of paper documents,Barcode or RFID technology is used to quickly and accurately identify single or multiple goods, and handheld or vehicle terminal is used to complete batch or refined operation of goods,Combined with the advanced backstage management system, the production and inventory of the whole warehouse can be monitored in real time.The scheme is suitable for all kinds of warehouse management enterprises, especially for those with large-scale warehouse

Solution system architecture

This scheme can automatically collect the data of each operation link, such as warehouse arrival inspection, warehousing, sorting, delivery, transfer, stock taking, etc,Through various wireless channels, handheld terminals and vehicle terminals, the collected data are uploaded to the background system in real time,Ensure the speed and accuracy of data input in each link of warehouse management, ensure that enterprises timely and accurately grasp the real inventory data,and reasonably ensure and control the inventory of enterprises.

1 Architecture

The first data acquisition layer: RFID tag, barcode, handheld terminal, vehicle terminal, fixed and antenna.

The second communication layer: WiFi, Bluetooth, GPRS, 3G, etc.

The third application layer: complete the processing of the collected data, including warehousing management, outbound management and location management.

The fourth data integration layer: complete the interconnection with other systems in the enterprise, and realize data sharing and transparency.

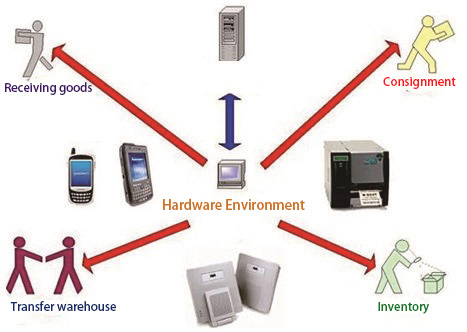

3 Hardware environment and technology

1.Automatic data collection: RFID wireless shooting technology can automatically collect the information of the type,brand and quantity of items in the out / in / out and sorting operations, so as to improve the speed of in and out of the warehouse;Automatically collect the information of goods on the shelf during inventory, reducing manual operation.

2.Document management: manages the receipt/issue documents and location adjustment documents of the daily operations of the warehouse.

Complete the functions of document entry, location allocation, instruction generation and monitoring.

3.Visual location management: when the system inventory is different from the actual inventory, the location inventory information is maintained.

4.Hardware equipment management: register and manage the handheld terminal, vehicle terminal and fixed reader in the warehouse.

5.Data query: various business documents can be queried in multiple dimensions and various statistical reports can be generated.

6.Provide external interface: help to transparency of information in supply chain and reduce safety stock of enterprises

2 Main functions of the system

1.Wireless network technology: through the reasonable deployment of wireless AP, wireless signals can cover any corner of the enterprise,Such a wireless network can provide a real-time data transmission path for warehousing enterprises, making all kinds of information unimpeded.

2.Handheld terminal and vehicle terminal: the warehouse staff can complete the work of receiving goods (binding goods with pallets), warehousing, shipping (goods and pallets unbound), goods transposition, goods unpacking, return processing, inventory checking and other work.The driver of the loading vehicle can use the vehicle to complete the warehousing (binding the pallet with the cargo location) and leaving the warehouse.

3.RFID Technology: RFID identification is a non-contact automatic identification technology.It includes tag and Reader writer Two parts.Tagj can identify target objects and obtain relevant data by radio signals, which can work in various harsh environments,And it can identify multiple tags at high speed

4.Bar code technology: bar code has the characteristics of fast identification speed, high recognition rate and low cost.

Home About Us Product RFID Case Studies New Solution Contact

Contact Us

phone:0086-0752-2688768

Cellphone:0086-0752-2688768

E-mail:yedyyip@thinkgo.cc

Zip code:516000

Address:Huinan Science and Technology Innovation Center, Nangaoxin Science and Technology Industrial Park, Huizhou City, Guangdong Province, China

© Copyright pinguan.co. ICP No.: 粤ICP备19133779号-1 Powered by www.gdwl.net.cn

All rights reserved Thinkgo IOT ICP:19133779

*Some materials are from the Internet, if there is infringement please inform us, we will delete * within 24 hours

yedyyip@thinkgo.cc

Tel

0086-0752-2688768

Address

Building 2, Huinan Science and Technology Innovation Center, Huizhou City, Guangdong Province, China

All rights reserved Thinkgo IOT ICP:19133779

* Materials are from the Internet, if there is infringement please inform us, we will delete within 24 hours